Specifying an Air Compressor Cooling System

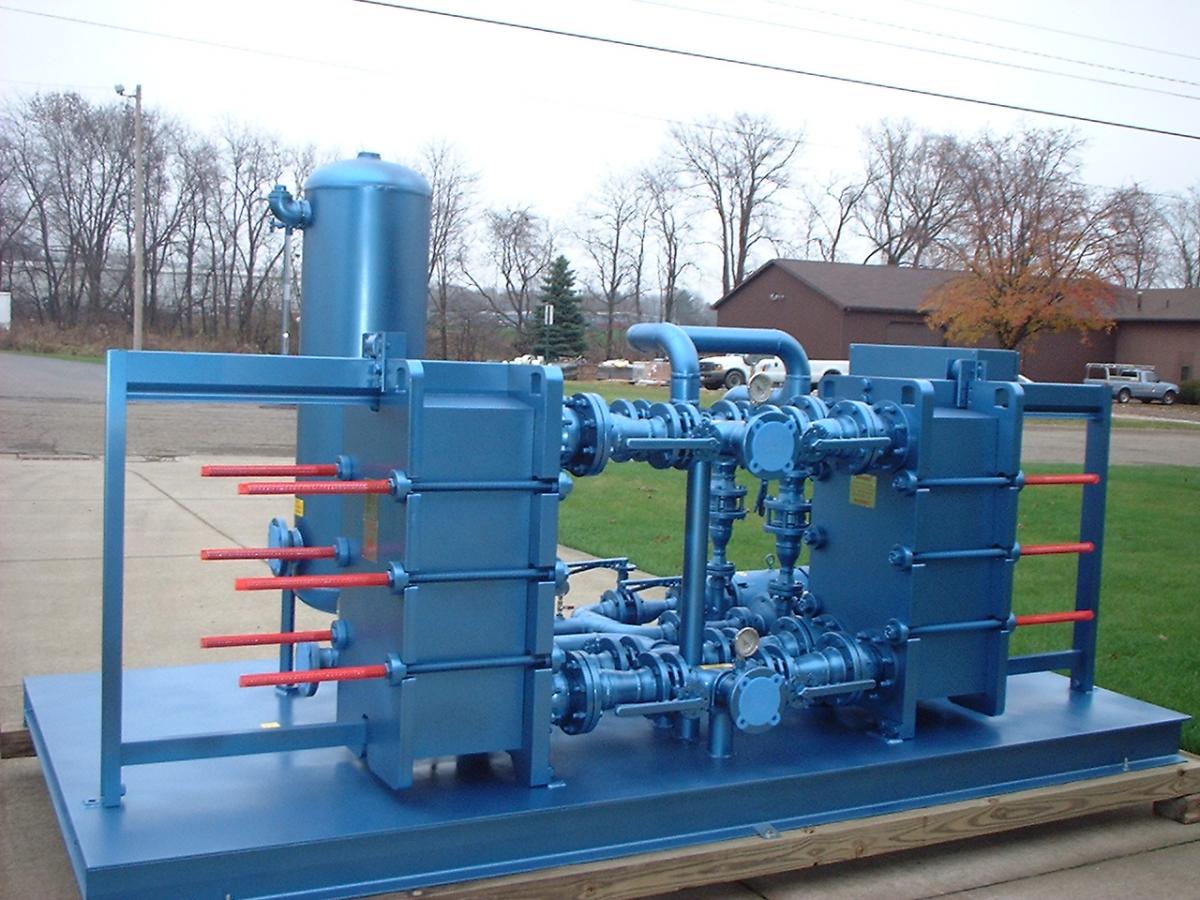

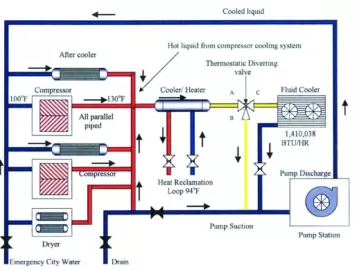

There are several pieces of information that your cooling system specialist will need in order to properly engineer and build a cooling system for your new air compressor. There are many types of air compressors and each has different requirements of the cooling system in order to operate correctly. This article will take the mystery out of some of the terms and specifications for your cooling system. In the previous article titled, “The Six Basic Types of Liquid Cooling Systems” (July 2013 Issue of Compressed Air Best Practices® Magazine), we gave a basic description of the different types of cooling systems and how they operated. This article will outline the basics of how one of those systems is employed to operate as an air compressor cooling system. We cannot possibly cover all of the variations of the different types of compressors nor how they are employed or how the location climate affects the operation of that compressor. One Sizing Scenario Therefore, we will choose one air compressor at a single location to give the reader an idea of what to provide to your cooling system specialist. For example: One 175 nameplate horsepower air compressor located in Scranton, PA. The building has a central open-cooling tower with an abundance of tower water available at a maximum temperature of 85 ⁰F. Power is available at 460Volts, 3 phase, 60Hz. There is a compressed air dryer in the system that will work properly with 100 ⁰F inlet air from the air compressor. At this point we need an air compressor data sheet to continue with the specification of the cooling system. In this example, the compressor data sheet gives us the actual maximum Brake Horse Power of the compressor to be 200 BHP. We use this information to determine the maximum heat load. Converting the brake horsepower to Btu/hr equals 509,000 Btu/hr. This is our heat load for the air compressor, if everything is operating perfectly. Normally, a margin is added to the system to reduce the effects of fouling, piping heat gain, inefficiencies in the system and condensation. For this example the customer wants us to use 30%. We simply multiply the load by 1.3 and we now have a design heat load of approximately 662,000 Btu/hr. The compressor data sheet tells us that the cooling system inlet temperature approach to the outlet air temperature is 10 ⁰F. This means that the outlet air temperature is regulated by the inlet cooling fluid temperature. Therefore, we need 90 ⁰F coolant temperature to provide an outlet air temperature of 100 ⁰F, a requirement for proper operation of the compressed air dryer. All of this can be achieved with a PCX (liquid to liquid) cooling system as discussed in our previous article.

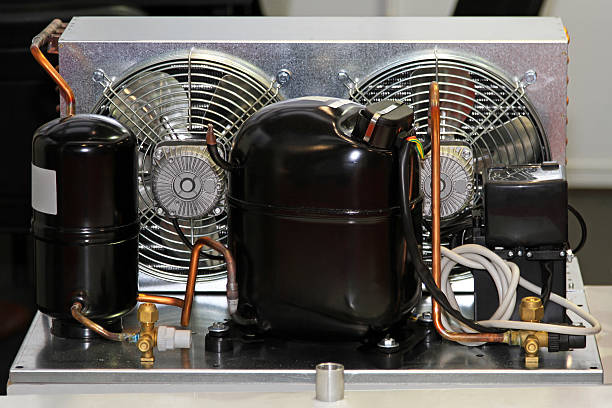

Refrigeration System - Types and working

Evaluating Air Compressor Cooling and Heat Recovery Part 2

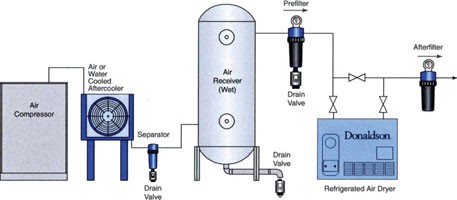

Process Design of Instrument Air System - InstrumentationTools

Compressor - Wikipedia

Specifying an Air Compressor Cooling System

Cooling Systems Compressed Air Best Practices

How to Select the Right Air Compressor for a New Plant

How long can you let an air compressor run for? Can you leave an

Air Compressor Buying Guide: 2033

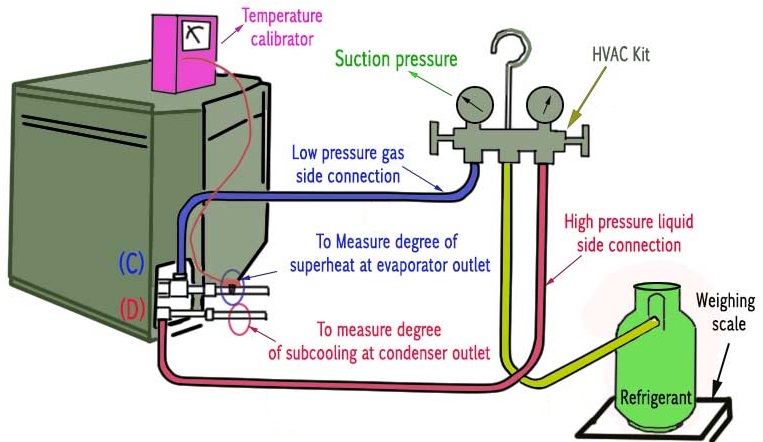

AC Refrigerant Compressor Replacement Procedure – Preventive

Air compressor troubleshooting

Energy-saving Opportunities in Compressed Air System

Energies, Free Full-Text

The Basics of Air Compressor On a Ship

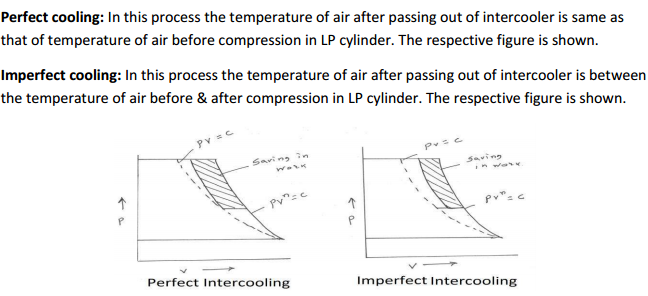

Define perfect and imperfect inter-cooling in air compressor and